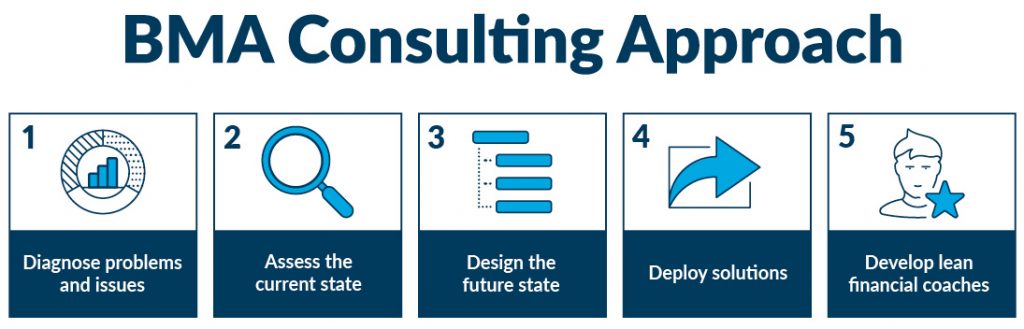

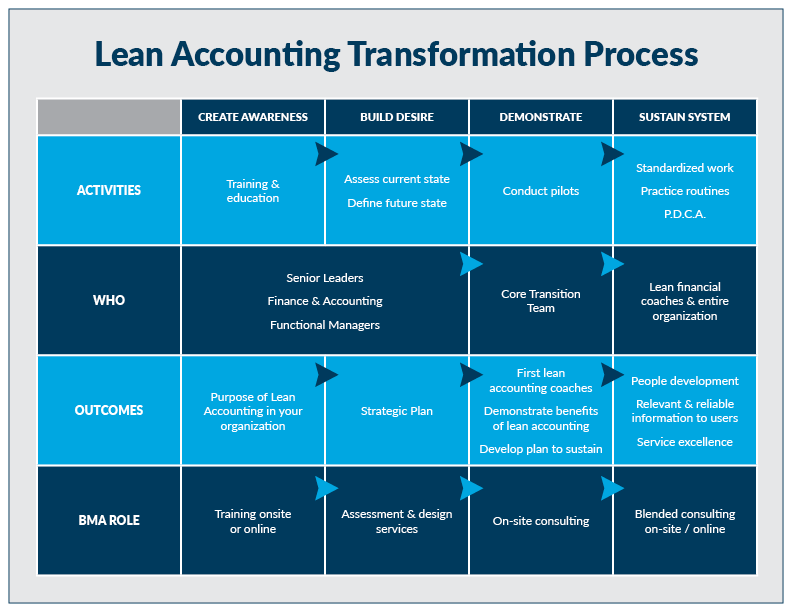

BMA’s lean consulting services offers practical solutions for businesses interested in implementing lean accounting. and lean management practices. Our approach is to facilitate kaizen events, leading a team through the process of achieving specific outcomes while providing them with the skills, experience and tools necessary to continue sustain your company’s lean accounting transformation.

We offer these consulting services on-site, remotely, or through a combined on-site/web-based approach.

BMA consulting is designed to facilitate a lean accounting transformation in the following areas:

- Lean Accounting Strategy Development

- Develop and coach accounting staff for lean leadership roles

- Accounting process improvement

- Align management accounting systems with lean strategy

BMA offers a FREE one-hour lean accounting consultation. Simply fill out the form below and we will contact you to set up an online consultation.

CLICK HERE to sign up for a Lean Accounting Assessment

Visit our BLOG page to learn more about lean accounting